Methanol Synthesis Flowsheet Example

Contents

###############################################################################

# The Institute for the Design of Advanced Energy Systems Integrated Platform

# Framework (IDAES IP) was produced under the DOE Institute for the

# Design of Advanced Energy Systems (IDAES).

#

# Copyright (c) 2018-2023 by the software owners: The Regents of the

# University of California, through Lawrence Berkeley National Laboratory,

# National Technology & Engineering Solutions of Sandia, LLC, Carnegie Mellon

# University, West Virginia University Research Corporation, et al.

# All rights reserved. Please see the files COPYRIGHT.md and LICENSE.md

# for full copyright and license information.

###############################################################################

Methanol Synthesis Flowsheet Example#

The purpose of this notebook is to demonstrate flowsheet synthesis integrating IDAES modeling tools, including the Unit Model Library, Property and Reaction Framework, IDAES scaling tools and the Process Costing Framework. The example leverages imports from external flowsheet scripts, and demonstrates implementation of separate VLE and vapor-only property packages to reduce model complexity where applicable.

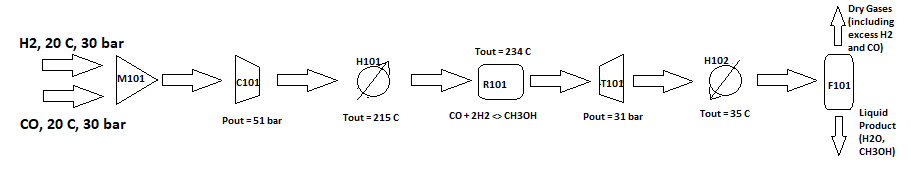

Simplified Hydrogen Reformation System#

This example demonstrates a steady-state model of methanol synthesis from hydrogen and carbon monoxide. To simulate relevant natural gas components, the reactant vapors are mixed stoichiometrically and brought to optimal reaction conditions prior to entering the gas-phase reactor. Vapor liquid equilibrium is mainly applicable in the post-reactor Flash unit for methanol recovery, and is accounted for by separate vapor and VLE thermophysical property packages. See methanol_flowsheet.py for more information on how to assemble the flowsheet, as well as idaes_examples.mod.methanol.methanol_ideal_VLE.py, idaes_examples.mod.methanol.methanol_ideal_vapor and idaes_examples.mod.methanol.methanol_reactions for more information on the thermophyscial and reaction properties.

This example is a reasonable approximation for gas-phase methanol synthesis systems and does not represent any particular chemical process. To simplify the system and increase tractability, hydrogen and carbon monoxide feeds are considered in lieu of multi-step mechanisms for carbon dioxide conversion to methanol. General process descriptions for gas-phase synthesis, as well as thermophysical and reaction properties for carbon monoxide hydrogenation, were taken from the following publication:

Nieminen, H.; Laari, A.; Koiranen, T. CO2 Hydrogenation to Methanol by a Liquid-Phase Process with Alcoholic Solvents: A Techno-Economic Analysis. Processes 2019, 7, 405. https://doi.org/10.3390/pr7070405

1. Introduction#

This example demonstrates a simulation of methanol synthesis from hydrogen and carbon monoxide. Each methanol flowsheet module includes several built-in methods. This notebook demonstrates building the flowsheet, implementing model scaling, initialization and solving a square problem, costing and final constrainted optimization.

The build_model() method creates the Pyomo concrete model and builds the flowsheet by importing thermophysical and reaction properties and unit models and defining stream connections between these units. This method also implements appropriate default scaling on state and property variables.

The set_inputs() method adds the appropriate initial specifications on the feed streams and unit operations. Specifications upstream of the reactor largely remain fixed throughout the optimization.

The scale_flowsheet() method implements generic variable, unit model state variable, unit model constraint and Arc equality constraint scaling via IDAES scaling tools. Scaling factors are hard-coded in the flowsheet scripts to adjust for order of magnitude factors in appropriate constraints and simplify numerical solver calculations.

The initialize_flowsheet() method uses the initial guess to initialize the models sequentially, solving each unit and propagating the results to the outlet stream to converge the next unit more quickly. This occurs just before the flowsheet-level solver call.

The add_costing() method creates new variables and constraints related to unit model capital cost and operating cost calculations, and defines an objective function for the process economics. This method is called after the flowsheet-level solver call, and the flowsheet is resolved once costing is added. Capital costs are estimated using built-in costing methods within IDAES, and operating costs are estimated from a combination of known cost coefficients and surrogate models.

The report() method displays relevant model results after the flowsheet has been fully solved.

2. Problem Statement#

For given raw material flows and optimal reactor conditions, we will calculate the extent of reaction, relevant process results including reactor duty and turbine duty, methanol recovery, and relevant economic results including annual revenue.

2.1. Main Inputs:#

Raw material inlets (F - mol/s, P - Pa, h - j/mol, x - mole fraction)

Pre-reactor compressor outlet pressure (Pa)

Pre-reactor heater outlet temperature (K)

2.2. Main Outputs:#

Extent of reaction (mol/s)

Reactor duty (W)

Turbine duty (W)

Methanol recovery (%)

Annual revenue (USD/year)

from IPython.display import Image

Image("methanol_flowsheet.png")

3. Import and Solve Flowsheet#

3.1 Import Pyomo and IDAES Libraries#

First, let’s import the relevant Pyomo and IDAES Libraries:

import pytest

import os

# Import Pyomo libraries

from pyomo.environ import (

Constraint,

Objective,

Var,

Expression,

Param,

ConcreteModel,

TransformationFactory,

value,

maximize,

units as pyunits,

)

from pyomo.environ import TerminationCondition

from pyomo.network import Arc

# Import IDAES core libraries

from idaes.core import FlowsheetBlock

from idaes_examples.mod.util import get_solver

from idaes.core.util import scaling as iscale

from idaes.core.util.model_statistics import degrees_of_freedom

from idaes.core.util.initialization import propagate_state

# Import required property modules

from idaes.models.properties.modular_properties.base.generic_property import (

GenericParameterBlock,

)

from idaes.models.properties.modular_properties.base.generic_reaction import (

GenericReactionParameterBlock,

)

from idaes_examples.mod.methanol import methanol_ideal_VLE as thermo_props_VLE

from idaes_examples.mod.methanol import methanol_ideal_vapor as thermo_props_vapor

from idaes_examples.mod.methanol import methanol_reactions as reaction_props

from idaes.models.unit_models import (

Feed,

Mixer,

Heater,

Compressor,

Turbine,

StoichiometricReactor,

Flash,

Product,

)

from idaes.models.unit_models.mixer import MomentumMixingType

from idaes.models.unit_models.pressure_changer import ThermodynamicAssumption

from idaes.core import UnitModelCostingBlock

from idaes.models.costing.SSLW import SSLWCosting

# import flowsheet functions

from methanol_flowsheet import (

build_model,

set_inputs,

scale_flowsheet,

initialize_flowsheet,

add_costing,

report,

)

3.2 Build and Solve Flowsheet#

The methanol flowsheet methods are called sequentially below, following the workflow contained in the main() method in methanol_flowsheet.py. First, let’s set the solver options. IDAES contains a default solver get_solver which calls IPOPT using standard settings, and we set an iteration cap of 100 to catch nonconverging solver runs.

# Set solver options

solver = get_solver() # IPOPT

optarg = {"tol": 1e-6, "max_iter": 100}

solver.options = optarg

Next, we will build and solve the initial flowsheet using imported flowsheet methods - see methanol_flowsheet.py for complete method scripts.

In the code below, we first define a Pyomo model object and build the model by defining each unit block with relevant property packages. As mentioned earlier, only the Flash unit (and the liquid outlet Product block) employ the VLE property package to ensure fast convergence of vapor-only processes.

The process inputs are set for stoichiometric hydrogen and carbon monoxide feeds according to the process diagram in section 2.2. In the output below, the script returns the expected degrees of freedom for the model for each unit (compressor pressure change, heater duty, reactor duty and conversion, turbine pressure change and efficiency, cooler duty and flash duty and pressure change) and the actual model degrees of freedom before input specification, after the feed inputs are specified (flow, enthalpy, pressure, and composition for each feed) and after the unit model inputs are specified.

After setting process inputs, we have a square problem for initialization. Here, we first implement IDAES scaling tools to create a more tractable problem during the solve step, and then sequentially initialize and propagate results from each unit block. As expected, the model only performs dew and bubble point calculations for the Flash and CH3OH product blocks where liquid phases are present and we obtain a square, solved problem:

# Build and solve flowsheet

m = ConcreteModel()

build_model(m) # build flowsheet by adding unit models and property packages

set_inputs(m) # unit and stream specifications

scale_flowsheet(m) # flowsheet and unit model level scaling

initialize_flowsheet(m) # rigorous initialization scheme

print("DOF before solve: ", degrees_of_freedom(m))

print()

print("Solving initial problem...")

results = solver.solve(m, tee=True) # initial square problem solve

Unit degrees of freedom

M101 0

C101 1

H101 1

R101 2

T101 2

H102 1

F101 2

Total DOF: 23

DOF after streams specified: 9

DOF after units specified: 0

2022-09-23 09:00:46 [INFO] idaes.init.fs.H2.properties: Starting initialization

2022-09-23 09:00:46 [INFO] idaes.init.fs.H2.properties: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:46 [INFO] idaes.init.fs.H2.properties: Property package initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:46 [INFO] idaes.init.fs.H2: Initialization Complete.

2022-09-23 09:00:46 [INFO] idaes.init.fs.CO.properties: Starting initialization

2022-09-23 09:00:46 [INFO] idaes.init.fs.CO.properties: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:46 [INFO] idaes.init.fs.CO.properties: Property package initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:46 [INFO] idaes.init.fs.CO: Initialization Complete.

2022-09-23 09:00:46 [INFO] idaes.init.fs.M101.H2_WGS_state: Starting initialization

2022-09-23 09:00:46 [INFO] idaes.init.fs.M101.H2_WGS_state: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:46 [INFO] idaes.init.fs.M101.CO_WGS_state: Starting initialization

2022-09-23 09:00:47 [INFO] idaes.init.fs.M101.CO_WGS_state: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:47 [INFO] idaes.init.fs.M101.mixed_state: Starting initialization

2022-09-23 09:00:47 [INFO] idaes.init.fs.M101.mixed_state: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:47 [INFO] idaes.init.fs.M101.mixed_state: Property package initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:47 [INFO] idaes.init.fs.M101: Initialization Complete: optimal - Optimal Solution Found

2022-09-23 09:00:47 [INFO] idaes.init.fs.C101.control_volume.properties_in: Starting initialization

2022-09-23 09:00:47 [INFO] idaes.init.fs.C101.control_volume.properties_in: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:47 [INFO] idaes.init.fs.C101.control_volume.properties_out: Starting initialization

2022-09-23 09:00:47 [INFO] idaes.init.fs.C101.control_volume.properties_out: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:47 [INFO] idaes.init.fs.C101.control_volume: Initialization Complete

2022-09-23 09:00:48 [INFO] idaes.init.fs.C101: Initialization Complete: optimal - Optimal Solution Found

2022-09-23 09:00:48 [INFO] idaes.init.fs.H101.control_volume.properties_in: Starting initialization

2022-09-23 09:00:48 [INFO] idaes.init.fs.H101.control_volume.properties_in: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:48 [INFO] idaes.init.fs.H101.control_volume.properties_out: Starting initialization

2022-09-23 09:00:48 [INFO] idaes.init.fs.H101.control_volume.properties_out: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:48 [INFO] idaes.init.fs.H101.control_volume: Initialization Complete

2022-09-23 09:00:48 [INFO] idaes.init.fs.H101: Initialization Complete: optimal - Optimal Solution Found

2022-09-23 09:00:48 [INFO] idaes.init.fs.R101.control_volume.properties_in: Starting initialization

2022-09-23 09:00:48 [INFO] idaes.init.fs.R101.control_volume.properties_in: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:48 [INFO] idaes.init.fs.R101.control_volume.properties_out: Starting initialization

2022-09-23 09:00:49 [INFO] idaes.init.fs.R101.control_volume.properties_out: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:49 [INFO] idaes.init.fs.R101.control_volume.reactions: Initialization Complete.

2022-09-23 09:00:49 [INFO] idaes.init.fs.R101.control_volume: Initialization Complete

2022-09-23 09:00:49 [INFO] idaes.init.fs.R101: Initialization Complete: optimal - Optimal Solution Found

2022-09-23 09:00:49 [INFO] idaes.init.fs.T101.control_volume.properties_in: Starting initialization

2022-09-23 09:00:49 [INFO] idaes.init.fs.T101.control_volume.properties_in: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:49 [INFO] idaes.init.fs.T101.control_volume.properties_out: Starting initialization

2022-09-23 09:00:49 [INFO] idaes.init.fs.T101.control_volume.properties_out: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:49 [INFO] idaes.init.fs.T101.control_volume.properties_out: Property package initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:49 [INFO] idaes.init.fs.T101.properties_isentropic: Starting initialization

2022-09-23 09:00:49 [INFO] idaes.init.fs.T101.properties_isentropic: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:49 [INFO] idaes.init.fs.T101.properties_isentropic: Property package initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:50 [INFO] idaes.init.fs.T101: Initialization Complete: optimal - Optimal Solution Found

2022-09-23 09:00:50 [INFO] idaes.init.fs.H102.control_volume.properties_in: Starting initialization

2022-09-23 09:00:50 [INFO] idaes.init.fs.H102.control_volume.properties_in: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:50 [INFO] idaes.init.fs.H102.control_volume.properties_out: Starting initialization

2022-09-23 09:00:50 [INFO] idaes.init.fs.H102.control_volume.properties_out: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:50 [INFO] idaes.init.fs.H102.control_volume: Initialization Complete

2022-09-23 09:00:50 [INFO] idaes.init.fs.H102: Initialization Complete: optimal - Optimal Solution Found

2022-09-23 09:00:50 [INFO] idaes.init.fs.F101.control_volume.properties_in: Starting initialization

2022-09-23 09:00:51 [INFO] idaes.init.fs.F101.control_volume.properties_in: Dew and bubble point initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:51 [INFO] idaes.init.fs.F101.control_volume.properties_in: Equilibrium temperature initialization completed.

2022-09-23 09:00:51 [INFO] idaes.init.fs.F101.control_volume.properties_in: Phase equilibrium initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:51 [INFO] idaes.init.fs.F101.control_volume.properties_in: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:51 [INFO] idaes.init.fs.F101.control_volume.properties_out: Starting initialization

2022-09-23 09:00:51 [INFO] idaes.init.fs.F101.control_volume.properties_out: Dew and bubble point initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:51 [INFO] idaes.init.fs.F101.control_volume.properties_out: Equilibrium temperature initialization completed.

2022-09-23 09:00:51 [INFO] idaes.init.fs.F101.control_volume.properties_out: Phase equilibrium initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:52 [INFO] idaes.init.fs.F101.control_volume.properties_out: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:52 [INFO] idaes.init.fs.F101.control_volume: Initialization Complete

2022-09-23 09:00:52 [INFO] idaes.init.fs.F101: Initialization Complete: optimal - Optimal Solution Found

2022-09-23 09:00:52 [INFO] idaes.init.fs.EXHAUST.properties: Starting initialization

2022-09-23 09:00:52 [INFO] idaes.init.fs.EXHAUST.properties: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:52 [INFO] idaes.init.fs.EXHAUST.properties: Property package initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:52 [INFO] idaes.init.fs.EXHAUST: Initialization Complete.

2022-09-23 09:00:52 [INFO] idaes.init.fs.CH3OH.properties: Starting initialization

2022-09-23 09:00:52 [INFO] idaes.init.fs.CH3OH.properties: Dew and bubble point initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:52 [INFO] idaes.init.fs.CH3OH.properties: Equilibrium temperature initialization completed.

2022-09-23 09:00:53 [INFO] idaes.init.fs.CH3OH.properties: Phase equilibrium initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:53 [INFO] idaes.init.fs.CH3OH.properties: Property initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:53 [INFO] idaes.init.fs.CH3OH.properties: Property package initialization: optimal - Optimal Solution Found.

2022-09-23 09:00:53 [INFO] idaes.init.fs.CH3OH: Initialization Complete.

DOF before solve: 0

Solving initial problem...

Ipopt 3.13.2: tol=1e-06

max_iter=100

******************************************************************************

This program contains Ipopt, a library for large-scale nonlinear optimization.

Ipopt is released as open source code under the Eclipse Public License (EPL).

For more information visit http://projects.coin-or.org/Ipopt

This version of Ipopt was compiled from source code available at

https://github.com/IDAES/Ipopt as part of the Institute for the Design of

Advanced Energy Systems Process Systems Engineering Framework (IDAES PSE

Framework) Copyright (c) 2018-2019. See https://github.com/IDAES/idaes-pse.

This version of Ipopt was compiled using HSL, a collection of Fortran codes

for large-scale scientific computation. All technical papers, sales and

publicity material resulting from use of the HSL codes within IPOPT must

contain the following acknowledgement:

HSL, a collection of Fortran codes for large-scale scientific

computation. See http://www.hsl.rl.ac.uk.

******************************************************************************

This is Ipopt version 3.13.2, running with linear solver ma27.

Number of nonzeros in equality constraint Jacobian...: 955

Number of nonzeros in inequality constraint Jacobian.: 0

Number of nonzeros in Lagrangian Hessian.............: 390

Total number of variables............................: 310

variables with only lower bounds: 35

variables with lower and upper bounds: 255

variables with only upper bounds: 1

Total number of equality constraints.................: 310

Total number of inequality constraints...............: 0

inequality constraints with only lower bounds: 0

inequality constraints with lower and upper bounds: 0

inequality constraints with only upper bounds: 0

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

0 0.0000000e+00 2.79e+04 1.00e+00 -1.0 0.00e+00 - 0.00e+00 0.00e+00 0

1 0.0000000e+00 2.79e+02 2.77e+00 -1.0 1.00e-02 - 9.90e-01 9.90e-01h 1

2 0.0000000e+00 2.77e+00 1.21e+00 -1.0 1.00e-04 - 9.90e-01 9.90e-01h 1

3 0.0000000e+00 3.52e-08 1.00e+03 -1.0 1.76e-06 - 9.90e-01 1.00e+00h 1

Number of Iterations....: 3

(scaled) (unscaled)

Objective...............: 0.0000000000000000e+00 0.0000000000000000e+00

Dual infeasibility......: 0.0000000000000000e+00 0.0000000000000000e+00

Constraint violation....: 1.8189894035458565e-12 3.5157427191734314e-08

Complementarity.........: 0.0000000000000000e+00 0.0000000000000000e+00

Overall NLP error.......: 1.8189894035458565e-12 3.5157427191734314e-08

Number of objective function evaluations = 4

Number of objective gradient evaluations = 4

Number of equality constraint evaluations = 4

Number of inequality constraint evaluations = 0

Number of equality constraint Jacobian evaluations = 4

Number of inequality constraint Jacobian evaluations = 0

Number of Lagrangian Hessian evaluations = 3

Total CPU secs in IPOPT (w/o function evaluations) = 0.008

Total CPU secs in NLP function evaluations = 0.002

EXIT: Optimal Solution Found.

3.3 Flowsheet Costing and Optimization#

Now that we have a well-initialized and solved flowsheet, we can add process economics and optimize the revenue. We utilize IDAES costing tools to calculate reactor and flash vessel capital cost, and implement surrogate models to account for heat exchanger capital costs. Additional, we calculate reactor operating costs as a function of conversion and assume constant rates for electricity, heating and cooling costs. Capital costs are annualized over 15 years, and revenue is determined from total liquid methanol sales, operating costs, annualized capital costs and feed raw material costs. The flowsheet report method returns key process results, including a check on the reaction stoichiometry, relevant duty and state variable values, economic results, and stream tables for feed and product streams:

add_costing(m) # re-solve with costing equations

print()

print("Solving with costing...")

results2 = solver.solve(m, tee=True)

print("Initial solution process results:")

report(m) # display initial solution results

Solving with costing...

Ipopt 3.13.2: tol=1e-06

max_iter=100

******************************************************************************

This program contains Ipopt, a library for large-scale nonlinear optimization.

Ipopt is released as open source code under the Eclipse Public License (EPL).

For more information visit http://projects.coin-or.org/Ipopt

This version of Ipopt was compiled from source code available at

https://github.com/IDAES/Ipopt as part of the Institute for the Design of

Advanced Energy Systems Process Systems Engineering Framework (IDAES PSE

Framework) Copyright (c) 2018-2019. See https://github.com/IDAES/idaes-pse.

This version of Ipopt was compiled using HSL, a collection of Fortran codes

for large-scale scientific computation. All technical papers, sales and

publicity material resulting from use of the HSL codes within IPOPT must

contain the following acknowledgement:

HSL, a collection of Fortran codes for large-scale scientific

computation. See http://www.hsl.rl.ac.uk.

******************************************************************************

This is Ipopt version 3.13.2, running with linear solver ma27.

Number of nonzeros in equality constraint Jacobian...: 971

Number of nonzeros in inequality constraint Jacobian.: 0

Number of nonzeros in Lagrangian Hessian.............: 392

Total number of variables............................: 319

variables with only lower bounds: 43

variables with lower and upper bounds: 255

variables with only upper bounds: 1

Total number of equality constraints.................: 319

Total number of inequality constraints...............: 0

inequality constraints with only lower bounds: 0

inequality constraints with lower and upper bounds: 0

inequality constraints with only upper bounds: 0

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

0 -2.8492051e+07 9.10e+04 1.00e+02 -1.0 0.00e+00 - 0.00e+00 0.00e+00 0

1 -2.9068962e+07 5.76e+04 6.45e+01 -1.0 1.20e+05 - 5.03e-02 9.90e-01h 1

2 -2.9074767e+07 5.71e+02 9.98e+00 -1.0 5.72e+04 - 9.81e-01 9.90e-01h 1

3 -2.9074825e+07 5.22e-05 1.00e+03 -1.0 5.67e+02 - 9.90e-01 1.00e+00h 1

4 -2.9074825e+07 1.16e-09 9.90e+04 -1.0 5.22e-05 - 9.90e-01 1.00e+00h 1

Number of Iterations....: 4

(scaled) (unscaled)

Objective...............: -4.4948186430824187e+01 -2.9074824816033270e+07

Dual infeasibility......: 4.9773460647709510e-07 3.2196063150335752e-01

Constraint violation....: 4.5474735088646412e-12 1.1641532182693481e-09

Complementarity.........: 0.0000000000000000e+00 0.0000000000000000e+00

Overall NLP error.......: 4.5474735088646412e-12 3.2196063150335752e-01

Number of objective function evaluations = 5

Number of objective gradient evaluations = 5

Number of equality constraint evaluations = 5

Number of inequality constraint evaluations = 0

Number of equality constraint Jacobian evaluations = 5

Number of inequality constraint Jacobian evaluations = 0

Number of Lagrangian Hessian evaluations = 4

Total CPU secs in IPOPT (w/o function evaluations) = 0.012

Total CPU secs in NLP function evaluations = 0.002

EXIT: Optimal Solution Found.

Initial solution process results:

Extent of reaction: 237.60047790000007

Stoichiometry of each component normalized by the extent:

CH4 : -0.0

H2 : -2.0

CH3OH : 1.0

CO : -1.0

These coefficients should follow 1*CO + 2*H2 => 1*CH3OH

Reaction conversion: 0.75

Reactor duty (MW): -45.21917830318437

Duty from Reaction (MW)): 21.536107316856008

Turbine work (MW): -0.959334644586757

Mixer outlet temperature (C)): 20.051714213753428

Compressor outlet temperature (C)): 20.051714213753485

Compressor outlet pressure (Pa)): 5100000.0

Heater outlet temperature (C)): 215.0

Reactor outlet temperature (C)): 234.0

Turbine outlet temperature (C)): 192.87815244243217

Turbine outlet pressure (Pa)): 3100000.0

Cooler outlet temperature (C)): 134.0

Flash outlet temperature (C)): 134.0

Methanol recovery(%): 60.00443012921689

annualized capital cost ($/year) = 219790.50447043357

operating cost ($/year) = 380701687.4964811

sales ($/year) = 64685201172.19819

raw materials cost ($/year) = 35229454878.16397

revenue (1000$/year)= 29074824.816033263

====================================================================================

Unit : fs.H2 Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Outlet

Total Molar Flowrate mole / second 637.20

Total Mole Fraction CH4 dimensionless 1.0000e-06

Total Mole Fraction CO dimensionless 1.0000e-06

Total Mole Fraction H2 dimensionless 1.0000

Total Mole Fraction CH3OH dimensionless 1.0000e-06

Molar Enthalpy joule / mole -142.40

Pressure pascal 3.0000e+06

====================================================================================

====================================================================================

Unit : fs.CO Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Outlet

Total Molar Flowrate mole / second 316.80

Total Mole Fraction CH4 dimensionless 1.0000e-06

Total Mole Fraction CO dimensionless 1.0000

Total Mole Fraction H2 dimensionless 1.0000e-06

Total Mole Fraction CH3OH dimensionless 1.0000e-06

Molar Enthalpy joule / mole -1.1068e+05

Pressure pascal 3.0000e+06

====================================================================================

====================================================================================

Unit : fs.EXHAUST Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Inlet

Total Molar Flowrate mole / second 336.23

Total Mole Fraction CH4 dimensionless 2.8373e-06

Total Mole Fraction CO dimensionless 0.23555

Total Mole Fraction H2 dimensionless 0.48181

Total Mole Fraction CH3OH dimensionless 0.28263

Molar Enthalpy joule / mole -80218.

Pressure pascal 3.1000e+06

====================================================================================

====================================================================================

Unit : fs.CH3OH Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Inlet

Total Molar Flowrate mole / second 142.57

Total Mole Fraction CH4 dimensionless 1.0000e-08

Total Mole Fraction CO dimensionless 1.0000e-08

Total Mole Fraction H2 dimensionless 1.0000e-08

Total Mole Fraction CH3OH dimensionless 1.0000

Molar Enthalpy joule / mole -2.3813e+05

Pressure pascal 3.1000e+06

====================================================================================

Finally, let’s unfix some specifications and determine an optimal revenue. We set bounds on our decision variables to constrain our objective to physical and economically sensible solutions. The pre-reactor section mixes the feeds and brings the reactants to optimal temperature and pressure, and we only unfix downstream unit specifications:

# Set up Optimization Problem (Maximize Revenue)

# keep process pre-reaction fixed and unfix some post-process specs

m.fs.R101.conversion.unfix()

m.fs.R101.conversion_lb = Constraint(expr=m.fs.R101.conversion >= 0.75)

m.fs.R101.conversion_ub = Constraint(expr=m.fs.R101.conversion <= 0.85)

m.fs.R101.outlet_temp.deactivate()

m.fs.R101.outlet_t_lb = Constraint(

expr=m.fs.R101.control_volume.properties_out[0.0].temperature >= 405 * pyunits.K

)

m.fs.R101.outlet_t_ub = Constraint(

expr=m.fs.R101.control_volume.properties_out[0.0].temperature <= 505 * pyunits.K

)

# Optimize turbine work (or delta P)

m.fs.T101.deltaP.unfix() # optimize turbine work recovery/pressure drop

m.fs.T101.outlet_p_lb = Constraint(

expr=m.fs.T101.outlet.pressure[0] >= 10e5 * pyunits.Pa

)

m.fs.T101.outlet_p_ub = Constraint(

expr=m.fs.T101.outlet.pressure[0] <= 51e5 * 0.8 * pyunits.Pa

)

# Optimize Cooler outlet temperature - unfix cooler outlet temperature

m.fs.H102.outlet_temp.deactivate()

m.fs.H102.outlet_t_lb = Constraint(

expr=m.fs.H102.control_volume.properties_out[0.0].temperature

>= 407.15 * 0.8 * pyunits.K

)

m.fs.H102.outlet_t_ub = Constraint(

expr=m.fs.H102.control_volume.properties_out[0.0].temperature <= 480 * pyunits.K

)

m.fs.F101.deltaP.unfix() # allow pressure change in streams

m.fs.F101.isothermal = Constraint(

expr=m.fs.F101.control_volume.properties_out[0].temperature

== m.fs.F101.control_volume.properties_in[0].temperature

)

print()

print("Solving optimization problem...")

opt_res = solver.solve(m, tee=True)

print("Optimal solution process results:")

report(m)

Solving optimization problem...

Ipopt 3.13.2: tol=1e-06

max_iter=100

******************************************************************************

This program contains Ipopt, a library for large-scale nonlinear optimization.

Ipopt is released as open source code under the Eclipse Public License (EPL).

For more information visit http://projects.coin-or.org/Ipopt

This version of Ipopt was compiled from source code available at

https://github.com/IDAES/Ipopt as part of the Institute for the Design of

Advanced Energy Systems Process Systems Engineering Framework (IDAES PSE

Framework) Copyright (c) 2018-2019. See https://github.com/IDAES/idaes-pse.

This version of Ipopt was compiled using HSL, a collection of Fortran codes

for large-scale scientific computation. All technical papers, sales and

publicity material resulting from use of the HSL codes within IPOPT must

contain the following acknowledgement:

HSL, a collection of Fortran codes for large-scale scientific

computation. See http://www.hsl.rl.ac.uk.

******************************************************************************

This is Ipopt version 3.13.2, running with linear solver ma27.

Number of nonzeros in equality constraint Jacobian...: 975

Number of nonzeros in inequality constraint Jacobian.: 8

Number of nonzeros in Lagrangian Hessian.............: 394

Total number of variables............................: 322

variables with only lower bounds: 43

variables with lower and upper bounds: 256

variables with only upper bounds: 1

Total number of equality constraints.................: 318

Total number of inequality constraints...............: 8

inequality constraints with only lower bounds: 4

inequality constraints with lower and upper bounds: 0

inequality constraints with only upper bounds: 4

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

0 -2.8492012e+07 2.79e+04 1.00e+02 -1.0 0.00e+00 - 0.00e+00 0.00e+00 0

1 -2.8402805e+07 2.72e+04 9.71e+01 -1.0 8.82e+06 - 4.99e-02 2.59e-02h 1

2 -2.8406590e+07 2.70e+04 9.56e+01 -1.0 8.57e+06 - 7.51e-02 8.58e-03h 1

3 -2.8493710e+07 2.29e+04 3.69e+02 -1.0 8.41e+06 - 1.67e-01 1.52e-01h 1

4 -2.8493256e+07 2.28e+04 1.20e+04 -1.0 4.60e+06 - 1.00e-01 2.61e-03h 1

5 -2.8504482e+07 2.24e+04 1.20e+04 -1.0 4.52e+06 - 2.44e-02 2.38e-02h 1

6 -2.8536507e+07 2.16e+04 2.28e+04 -1.0 4.39e+06 - 5.48e-02 6.86e-02h 1

7 -2.8537588e+07 2.16e+04 1.35e+05 -1.0 3.94e+06 - 2.56e-01 2.49e-03h 1

8 -2.8537637e+07 2.15e+04 6.77e+06 -1.0 1.30e+06 - 4.69e-01 1.17e-04h 1

9 -2.8910081e+07 8.51e+04 2.07e+06 -1.0 1.31e+06 - 4.38e-01 9.05e-01h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

10 -2.8914184e+07 7.59e+04 7.45e+06 -1.0 9.51e+04 - 9.00e-01 1.08e-01h 1

11 -2.8947682e+07 1.17e+03 1.82e+05 -1.0 8.76e+04 - 9.09e-01 9.90e-01h 1

12 -2.8918208e+07 1.81e+01 3.80e+06 -1.0 6.65e+03 - 9.89e-01 9.92e-01h 1

13 -3.9622915e+07 3.82e+04 5.44e+08 -1.0 5.15e+06 - 1.20e-01 1.75e-01f 3

14 -5.4538471e+07 7.75e+04 2.91e+08 -1.0 1.98e+06 - 6.35e-01 1.00e+00F 1

15 -5.8427164e+07 1.46e+05 2.83e+06 -1.0 1.61e+06 - 6.74e-01 9.97e-01f 1

16 -6.3179254e+07 1.83e+04 2.76e+06 -1.0 2.06e+06 - 2.01e-02 1.00e+00f 1

17 -6.8685110e+07 4.27e+04 2.75e+06 -1.0 1.18e+09 - 1.83e-03 1.66e-03f 2

18 -6.8948716e+07 1.02e+02 6.64e+05 -1.0 3.00e+04 -4.0 9.90e-01 1.00e+00h 1

19 -6.8948602e+07 2.50e-03 4.50e+03 -1.0 2.68e+02 -4.5 9.97e-01 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

20 -6.8948605e+07 9.31e-10 1.20e-02 -1.0 3.72e-01 -5.0 1.00e+00 1.00e+00h 1

21 -6.8948615e+07 2.10e-08 5.43e-01 -5.7 1.09e+00 -5.4 1.00e+00 1.00e+00f 1

22 -6.8948643e+07 1.61e-07 4.02e-06 -5.7 3.26e+00 -5.9 1.00e+00 1.00e+00f 1

23 -6.8948729e+07 1.44e-06 9.00e-05 -8.6 9.78e+00 -6.4 1.00e+00 1.00e+00f 1

24 -6.8948988e+07 1.30e-05 4.02e-06 -8.6 2.93e+01 -6.9 1.00e+00 1.00e+00f 1

25 -6.8949763e+07 1.17e-04 4.02e-06 -8.6 8.80e+01 -7.3 1.00e+00 1.00e+00f 1

26 -6.8952089e+07 1.05e-03 4.02e-06 -8.6 2.64e+02 -7.8 1.00e+00 1.00e+00f 1

27 -6.8959067e+07 9.45e-03 4.02e-06 -8.6 7.92e+02 -8.3 1.00e+00 1.00e+00f 1

28 -6.8980000e+07 8.50e-02 6.98e-06 -8.6 2.38e+03 -8.8 1.00e+00 1.00e+00f 1

29 -6.9042802e+07 7.66e-01 6.28e-05 -8.6 7.13e+03 -9.2 1.00e+00 1.00e+00f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

30 -6.9231219e+07 6.91e+00 5.66e-04 -8.6 2.14e+04 -9.7 1.00e+00 1.00e+00f 1

31 -6.9796592e+07 6.28e+01 5.10e-03 -8.6 6.41e+04 -10.2 1.00e+00 1.00e+00f 1

32 -6.9969537e+07 6.24e+01 5.06e-03 -8.6 1.92e+05 -10.7 1.00e+00 1.02e-01f 1

33 -7.0739937e+07 1.53e+02 5.52e-01 -8.6 7.09e+05 -11.2 1.00e+00 2.88e-01f 1

34 -7.6386902e+07 6.17e+03 8.19e+00 -8.6 1.96e+06 -11.6 1.00e+00 7.75e-01f 1

35r-7.6386902e+07 6.17e+03 9.99e+02 1.0 0.00e+00 - 0.00e+00 2.68e-10R 3

36r-7.6386917e+07 6.17e+03 9.99e+02 1.0 1.03e+10 - 6.44e-09 1.35e-11f 2

37r-7.6863689e+07 1.23e+04 6.43e+04 1.0 5.82e+05 - 2.18e-06 1.92e-04f 1

38 -7.8373774e+07 4.30e+04 1.74e+02 -8.6 4.25e+13 - 1.55e-07 2.00e-08f 1

In iteration 38, 1 Slack too small, adjusting variable bound

39 -7.8374386e+07 4.30e+04 1.74e+02 -8.6 7.42e+09 - 8.33e-04 2.53e-08f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

40 -7.8381465e+07 4.30e+04 3.06e+02 -8.6 2.81e+06 - 1.00e+00 8.33e-04h 1

41 -7.7718831e+07 1.15e+04 8.17e+00 -8.6 4.30e+04 - 1.00e+00 9.73e-01h 1

42 -7.7700537e+07 1.09e+02 2.50e-01 -8.6 1.84e+03 - 1.00e+00 1.00e+00h 1

43 -7.7700536e+07 6.02e-03 4.18e-01 -8.6 4.93e+00 - 9.11e-01 1.00e+00h 1

44 -7.7700536e+07 3.73e-09 2.43e-03 -8.6 2.82e-03 - 1.00e+00 1.00e+00h 1

45 -7.7700536e+07 2.79e-09 2.27e-13 -8.6 2.60e-08 - 1.00e+00 1.00e+00h 1

46 -7.7700536e+07 1.86e-09 6.97e-11 -10.9 2.16e+00 - 1.00e+00 1.00e+00h 1

Number of Iterations....: 46

(scaled) (unscaled)

Objective...............: -1.2012103932731618e+02 -7.7700535939009801e+07

Dual infeasibility......: 6.9715324770738830e-11 4.5095498075803740e-05

Constraint violation....: 9.4587448984384537e-11 1.8626451492309570e-09

Complementarity.........: 1.4074776814316710e-11 9.1042976968786751e-06

Overall NLP error.......: 9.4587448984384537e-11 4.5095498075803740e-05

Number of objective function evaluations = 60

Number of objective gradient evaluations = 46

Number of equality constraint evaluations = 60

Number of inequality constraint evaluations = 60

Number of equality constraint Jacobian evaluations = 48

Number of inequality constraint Jacobian evaluations = 48

Number of Lagrangian Hessian evaluations = 46

Total CPU secs in IPOPT (w/o function evaluations) = 0.125

Total CPU secs in NLP function evaluations = 0.042

EXIT: Optimal Solution Found.

Optimal solution process results:

Extent of reaction: 269.280544787992

Stoichiometry of each component normalized by the extent:

CH4 : 0.0

H2 : -2.0

CH3OH : 1.0

CO : -1.0

These coefficients should follow 1*CO + 2*H2 => 1*CH3OH

Reaction conversion: 0.8500000099999546

Reactor duty (MW): -51.36357357754579

Duty from Reaction (MW)): 24.407588579583596

Turbine work (MW): -1.9904899177794952

Mixer outlet temperature (C)): 20.05171421375354

Compressor outlet temperature (C)): 20.0517142137536

Compressor outlet pressure (Pa)): 5100000.0

Heater outlet temperature (C)): 215.0

Reactor outlet temperature (C)): 231.8500046871659

Turbine outlet temperature (C)): 139.85888172675635

Turbine outlet pressure (Pa)): 1427653.3547820952

Cooler outlet temperature (C)): 52.56999709299214

Flash outlet temperature (C)): 134.0

Methanol recovery(%): 92.80355474669571

annualized capital cost ($/year) = 235547.18924473264

operating cost ($/year) = 451663512.68477196

sales ($/year) = 113381889877.04779

raw materials cost ($/year) = 35229454878.16397

revenue (1000$/year)= 77700535.93900982

====================================================================================

Unit : fs.H2 Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Outlet

Total Molar Flowrate mole / second 637.20

Total Mole Fraction CH4 dimensionless 1.0000e-06

Total Mole Fraction CO dimensionless 1.0000e-06

Total Mole Fraction H2 dimensionless 1.0000

Total Mole Fraction CH3OH dimensionless 1.0000e-06

Molar Enthalpy joule / mole -142.40

Pressure pascal 3.0000e+06

====================================================================================

====================================================================================

Unit : fs.CO Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Outlet

Total Molar Flowrate mole / second 316.80

Total Mole Fraction CH4 dimensionless 1.0000e-06

Total Mole Fraction CO dimensionless 1.0000

Total Mole Fraction H2 dimensionless 1.0000e-06

Total Mole Fraction CH3OH dimensionless 1.0000e-06

Molar Enthalpy joule / mole -1.1068e+05

Pressure pascal 3.0000e+06

====================================================================================

====================================================================================

Unit : fs.EXHAUST Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Inlet

Total Molar Flowrate mole / second 165.54

Total Mole Fraction CH4 dimensionless 5.7630e-06

Total Mole Fraction CO dimensionless 0.28706

Total Mole Fraction H2 dimensionless 0.59587

Total Mole Fraction CH3OH dimensionless 0.11706

Molar Enthalpy joule / mole -52313.

Pressure pascal 7.4845e+06

====================================================================================

====================================================================================

Unit : fs.CH3OH Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Inlet

Total Molar Flowrate mole / second 249.90

Total Mole Fraction CH4 dimensionless 1.0000e-08

Total Mole Fraction CO dimensionless 1.0000e-08

Total Mole Fraction H2 dimensionless 1.0000e-08

Total Mole Fraction CH3OH dimensionless 1.0000

Molar Enthalpy joule / mole -2.3792e+05

Pressure pascal 7.4845e+06

====================================================================================

As expected, the process achieves a much greater revenue as a result of increasing conversion and lowering the inlet temperature to the Flash unit to encourage methanol recovery in the liquid phase. The results show a slight increase in equipment and operating costs from these changes, as well as a small loss of methanol in the exhuast.

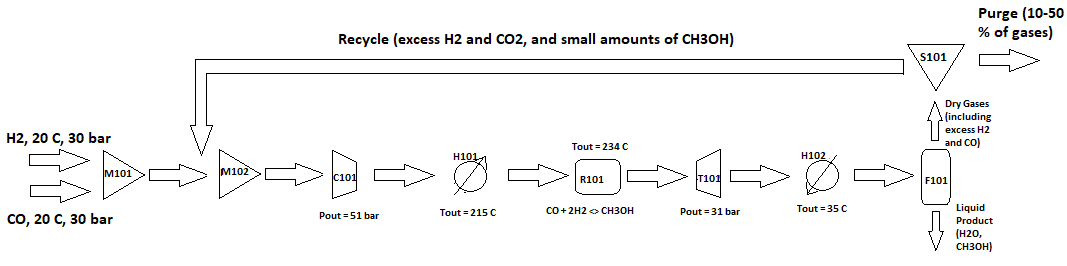

4. Problem Statement - Analyzing Benefit of Recycling Flash Vapor#

To increase the efficiency of the process as well as overall methanol production and revenue, we can add a recycle stream to send most of the Flash vapor back to the start of the process. This will reduce methanol loss in the exhaust and increase feed utilization, resulting in increased operating costs and increased production (revenue) at the same conversion. Note that for conversions less than 100%, a simulation with no purge will never converge due to accumulation of gases within the system. Therefore, to ensure we close the mass balance we set a lower bound at 10% purge from the Flash vapor to the exhaust. We expect to see a marginal increase in operating costs due to increased flow, and a much larger increase in overall production resulting in a higher total revenue.

By adding a recycle to the flowsheet, we significantly decrease the tractability of the problem and require a better initial guess. The SequentialDecomposition algorithm automatically determines a stream to tear, or use to break the solve loop, and iterates from a set of user-supplied initial guesses until converging on the optimal solution. The code below calls an initialization method to automatically determine the tear stream. See the initialization method of methanol_flowsheet_w_recycle.py for further details Sequential Decomposition scheme.

For given raw material flows and optimal reactor conditions, we will calculate the extent of reaction, relevant process results including reactor duty and turbine duty, methanol recovery, and relevant economic results including annual revenue.

4.1. Main Inputs:#

Raw material inlets (F - mol/s, P - Pa, h - j/mol, x - mole fraction)

Pre-reactor compressor outlet pressure (Pa)

Pre-reactor heater outlet temperature (K)

4.2. Main Outputs:#

Extent of reaction (mol/s)

Reactor duty (W)

Compressor duty (W)

Turbine duty (W)

Methanol recovery (%)

Purge percentage (%)

Annual revenue (USD/year)

from IPython.display import Image

Image("methanol_flowsheet_recycle.png")

5. Import and Solve Recycle Flowsheet#

5.1 Import Pyomo and IDAES Libraries#

As we are rebuilding the model, we need to import require Pyomo and IDAES libraries:

import pytest

import os

# Import Pyomo libraries

from pyomo.environ import (

Constraint,

Objective,

Var,

Expression,

Param,

ConcreteModel,

TransformationFactory,

value,

maximize,

units as pyunits,

)

from pyomo.environ import TerminationCondition

from pyomo.network import Arc, SequentialDecomposition

# Import IDAES core libraries

from idaes.core import FlowsheetBlock

from idaes_examples.mod.util import get_solver

from idaes.core.util import scaling as iscale

from idaes.core.util.model_statistics import degrees_of_freedom

from idaes.core.util.initialization import propagate_state

# Import required models

from idaes.models.properties.modular_properties.base.generic_property import (

GenericParameterBlock,

)

from idaes.models.properties.modular_properties.base.generic_reaction import (

GenericReactionParameterBlock,

)

from idaes_examples.mod.methanol import methanol_ideal_VLE as thermo_props_VLE

from idaes_examples.mod.methanol import methanol_ideal_vapor as thermo_props_vapor

from idaes_examples.mod.methanol import methanol_reactions as reaction_props

from idaes.models.unit_models import (

Feed,

Mixer,

Heater,

Compressor,

Turbine,

StoichiometricReactor,

Flash,

Separator as Splitter,

Product,

)

from idaes.models.unit_models.mixer import MomentumMixingType

from idaes.models.unit_models.pressure_changer import ThermodynamicAssumption

from idaes.core import UnitModelCostingBlock

from idaes.models.costing.SSLW import SSLWCosting

import idaes.logger as idaeslog

# import flowsheet functions

from methanol_flowsheet_w_recycle import (

build_model,

set_inputs,

scale_flowsheet,

initialize_flowsheet,

add_costing,

report,

)

5.2 Build and Solve Recycle Flowsheet#

As before, we will first build the flowsheet, set required inputs, initialize and solve a square problem. Recycling methanol to pre-reactor blocks complicates VLE calculations, and limiting VLE calculations to the Flash unit and liquid Product block greatly increases tractability during initialization. All initial feed and unit specifications are identical to the non-recycle case; the Sequential Decomposition algorithm automatically selects the compressor feed as the tear stream and uses “no recycle” results as a first guess. In the output below, the solver solves all units and then resolves select blocks with updated inlet results, followed by a full flowsheet solve:

# Build and solve flowsheet

solver = get_solver() # IPOPT

optarg = {"tol": 1e-6, "max_iter": 100}

solver.options = optarg

m = ConcreteModel() # create a new model so we may reference 'm' below

build_model(m) # build flowsheet

set_inputs(m) # unit and stream specifications

scale_flowsheet(m) # flowsheet and unit model level scaling

# let the solver determine the tear stream

initialize_flowsheet(m) # rigorous initialization scheme

print("DOF before solve: ", degrees_of_freedom(m))

print()

print("Solving initial problem...")

results = solver.solve(m, tee=True)

Unit degrees of freedom

M101 0

C101 1

H101 1

R101 2

T101 2

H102 1

F101 2

M102 0

S101 1

Total DOF: 24

DOF after streams specified: 10

DOF after units specified: 0

Tear Stream:

fs.s02 : fs.M102.outlet to fs.C101.inlet

Calculation order:

fs.H2

fs.M101

fs.R101

fs.T101

fs.H102

fs.F101

fs.S101

fs.EXHAUST

Initial DOF = 0

Solving fs.H2

DOF = 0

Solving fs.CO

DOF = 0

Solving fs.C101

DOF = 0

Solving fs.M101

DOF = 0

Solving fs.H101

DOF = 0

Solving fs.R101

DOF = 0

Solving fs.T101

DOF = 0

Solving fs.H102

DOF = 0

Solving fs.F101

DOF = 0

Solving fs.S101

DOF = 0

Solving fs.CH3OH

DOF = 0

Solving fs.EXHAUST

DOF = 0

Solving fs.M102

DOF = 0

Solving fs.H2

DOF = 0

Solving fs.CO

DOF = 0

Solving fs.M101

DOF = 0

Solving fs.EXHAUST

DOF = 0

Solving fs.CH3OH

DOF = 0

Final DOF = 0

DOF before solve: 0

Solving initial problem...

Ipopt 3.13.2: tol=1e-06

max_iter=100

******************************************************************************

This program contains Ipopt, a library for large-scale nonlinear optimization.

Ipopt is released as open source code under the Eclipse Public License (EPL).

For more information visit http://projects.coin-or.org/Ipopt

This version of Ipopt was compiled from source code available at

https://github.com/IDAES/Ipopt as part of the Institute for the Design of

Advanced Energy Systems Process Systems Engineering Framework (IDAES PSE

Framework) Copyright (c) 2018-2019. See https://github.com/IDAES/idaes-pse.

This version of Ipopt was compiled using HSL, a collection of Fortran codes

for large-scale scientific computation. All technical papers, sales and

publicity material resulting from use of the HSL codes within IPOPT must

contain the following acknowledgement:

HSL, a collection of Fortran codes for large-scale scientific

computation. See http://www.hsl.rl.ac.uk.

******************************************************************************

This is Ipopt version 3.13.2, running with linear solver ma27.

Number of nonzeros in equality constraint Jacobian...: 1211

Number of nonzeros in inequality constraint Jacobian.: 0

Number of nonzeros in Lagrangian Hessian.............: 485

Total number of variables............................: 397

variables with only lower bounds: 41

variables with lower and upper bounds: 333

variables with only upper bounds: 1

Total number of equality constraints.................: 397

Total number of inequality constraints...............: 0

inequality constraints with only lower bounds: 0

inequality constraints with lower and upper bounds: 0

inequality constraints with only upper bounds: 0

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

0 0.0000000e+00 2.79e+04 1.00e+00 -1.0 0.00e+00 - 0.00e+00 0.00e+00 0

1 0.0000000e+00 2.79e+02 4.22e+03 -1.0 1.96e+03 - 9.90e-01 9.90e-01h 1

2 0.0000000e+00 2.77e+00 3.86e+03 -1.0 2.03e+01 - 9.90e-01 9.90e-01h 1

3 0.0000000e+00 7.44e-06 1.01e+03 -1.0 2.01e-01 - 9.90e-01 1.00e+00h 1

Number of Iterations....: 3

(scaled) (unscaled)

Objective...............: 0.0000000000000000e+00 0.0000000000000000e+00

Dual infeasibility......: 0.0000000000000000e+00 0.0000000000000000e+00

Constraint violation....: 2.4014227693119351e-10 7.4444105848670006e-06

Complementarity.........: 0.0000000000000000e+00 0.0000000000000000e+00

Overall NLP error.......: 2.4014227693119351e-10 7.4444105848670006e-06

Number of objective function evaluations = 4

Number of objective gradient evaluations = 4

Number of equality constraint evaluations = 4

Number of inequality constraint evaluations = 0

Number of equality constraint Jacobian evaluations = 4

Number of inequality constraint Jacobian evaluations = 0

Number of Lagrangian Hessian evaluations = 3

Total CPU secs in IPOPT (w/o function evaluations) = 0.014

Total CPU secs in NLP function evaluations = 0.001

EXIT: Optimal Solution Found.

5.3 Flowsheet Costing and Optimization#

Now that we have a well-initialized and solved flowsheet, we can add process economics and optimize the revenue. We utilize IDAES costing tools to calculate reactor and flash vessel capital cost, and implement surrogate models to account for heat exchanger capital costs, reactor operating costs and utility costs for heating, cooling and electricity. As before, revenue is determined from total liquid methanol sales, operating costs, annualized capital costs and feed raw material costs. The flowsheet report method returns key process results, which are updated for new results with the prescence of a recycle stream:

add_costing(m) # re-solve with costing equations

print()

results2 = solver.solve(m, tee=True)

print("Initial solution process results:")

report(m) # display initial solution results

Ipopt 3.13.2: tol=1e-06

max_iter=100

******************************************************************************

This program contains Ipopt, a library for large-scale nonlinear optimization.

Ipopt is released as open source code under the Eclipse Public License (EPL).

For more information visit http://projects.coin-or.org/Ipopt

This version of Ipopt was compiled from source code available at

https://github.com/IDAES/Ipopt as part of the Institute for the Design of

Advanced Energy Systems Process Systems Engineering Framework (IDAES PSE

Framework) Copyright (c) 2018-2019. See https://github.com/IDAES/idaes-pse.

This version of Ipopt was compiled using HSL, a collection of Fortran codes

for large-scale scientific computation. All technical papers, sales and

publicity material resulting from use of the HSL codes within IPOPT must

contain the following acknowledgement:

HSL, a collection of Fortran codes for large-scale scientific

computation. See http://www.hsl.rl.ac.uk.

******************************************************************************

This is Ipopt version 3.13.2, running with linear solver ma27.

Number of nonzeros in equality constraint Jacobian...: 1227

Number of nonzeros in inequality constraint Jacobian.: 0

Number of nonzeros in Lagrangian Hessian.............: 487

Total number of variables............................: 406

variables with only lower bounds: 49

variables with lower and upper bounds: 333

variables with only upper bounds: 1

Total number of equality constraints.................: 406

Total number of inequality constraints...............: 0

inequality constraints with only lower bounds: 0

inequality constraints with lower and upper bounds: 0

inequality constraints with only upper bounds: 0

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

0 -2.8497869e+07 9.10e+04 1.00e+02 -1.0 0.00e+00 - 0.00e+00 0.00e+00 0

1 -2.9074832e+07 5.76e+04 4.22e+03 -1.0 1.20e+05 - 5.03e-02 9.90e-01h 1

2 -2.9080637e+07 5.71e+02 3.82e+03 -1.0 5.72e+04 - 9.81e-01 9.90e-01h 1

3 -2.9080695e+07 5.22e-05 1.00e+03 -1.0 5.67e+02 - 9.90e-01 1.00e+00h 1

4 -2.9080695e+07 9.31e-10 9.90e+04 -1.0 5.22e-05 - 9.90e-01 1.00e+00h 1

Cannot recompute multipliers for feasibility problem. Error in eq_mult_calculator

Number of Iterations....: 4

(scaled) (unscaled)

Objective...............: -4.4953175283791957e+01 -2.9080695361147862e+07

Dual infeasibility......: 9.9999999999985807e+06 6.4691081725719365e+12

Constraint violation....: 4.5474735088646412e-12 9.3132257461547852e-10

Complementarity.........: 0.0000000000000000e+00 0.0000000000000000e+00

Overall NLP error.......: 4.5474735088646412e-12 6.4691081725719365e+12

Number of objective function evaluations = 5

Number of objective gradient evaluations = 5

Number of equality constraint evaluations = 5

Number of inequality constraint evaluations = 0

Number of equality constraint Jacobian evaluations = 5

Number of inequality constraint Jacobian evaluations = 0

Number of Lagrangian Hessian evaluations = 4

Total CPU secs in IPOPT (w/o function evaluations) = 0.019

Total CPU secs in NLP function evaluations = 0.006

EXIT: Optimal Solution Found.

Initial solution process results:

Extent of reaction: 237.60641806045155

Stoichiometry of each component normalized by the extent:

CH4 : 0.0

H2 : -2.0

CH3OH : 1.0

CO : -1.0

These coefficients should follow 1*CO + 2*H2 => 1*CH3OH

Reaction conversion: 0.75

Reactor duty (MW): -45.22029794711382

Duty from Reaction (MW)): 21.53664573299933

Compressor work (MW): 5.435710250273887e-19

Turbine work (MW): -0.9593785023914432

Feed Mixer outlet temperature (C)): 20.0517142137536

Recycle Mixer outlet temperature (C)): 20.056485612776214

Feed Compressor outlet temperature (C)): 20.05648561277644

Feed Compressor outlet pressure (Pa)): 5100000.0

Heater outlet temperature (C)): 215.0

Reactor outlet temperature (C)): 234.0

Turbine outlet temperature (C)): 192.87840947667888

Turbine outlet pressure (Pa)): 3100000.0

Cooler outlet temperature (C)): 134.0

Flash outlet temperature (C)): 134.0

Purge percentage (amount of vapor vented to exhaust): 99.99 %

Methanol recovery(%): 60.005984934911716

annualized capital cost ($/year) = 219794.2325658718

operating cost ($/year) = 380711692.18369997

sales ($/year) = 64691081725.72809

raw materials cost ($/year) = 35229454878.16397

revenue (1000$/year)= 29080695.36114785

====================================================================================

Unit : fs.H2 Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Outlet

Total Molar Flowrate mole / second 637.20

Total Mole Fraction CH4 dimensionless 1.0000e-06

Total Mole Fraction CO dimensionless 1.0000e-06

Total Mole Fraction H2 dimensionless 1.0000

Total Mole Fraction CH3OH dimensionless 1.0000e-06

Molar Enthalpy joule / mole -142.40

Pressure pascal 3.0000e+06

====================================================================================

====================================================================================

Unit : fs.CO Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Outlet

Total Molar Flowrate mole / second 316.80

Total Mole Fraction CH4 dimensionless 1.0000e-06

Total Mole Fraction CO dimensionless 1.0000

Total Mole Fraction H2 dimensionless 1.0000e-06

Total Mole Fraction CH3OH dimensionless 1.0000e-06

Molar Enthalpy joule / mole -1.1068e+05

Pressure pascal 3.0000e+06

====================================================================================

====================================================================================

Unit : fs.EXHAUST Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Inlet

Total Molar Flowrate mole / second 336.21

Total Mole Fraction CH4 dimensionless 2.8375e-06

Total Mole Fraction CO dimensionless 0.23555

Total Mole Fraction H2 dimensionless 0.48181

Total Mole Fraction CH3OH dimensionless 0.28263

Molar Enthalpy joule / mole -80218.

Pressure pascal 3.1000e+06

====================================================================================

====================================================================================

Unit : fs.CH3OH Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Inlet

Total Molar Flowrate mole / second 142.58

Total Mole Fraction CH4 dimensionless 1.0000e-08

Total Mole Fraction CO dimensionless 1.0000e-08

Total Mole Fraction H2 dimensionless 1.0000e-08

Total Mole Fraction CH3OH dimensionless 1.0000

Molar Enthalpy joule / mole -2.3813e+05

Pressure pascal 3.1000e+06

====================================================================================

Finally, let’s unfix some specifications and determine an optimal revenue. We set bounds on our decision variables to constrain our objective to physical and economically sensible solutions, including a purge between 10-50% of flash vapor. The pre-reactor section mixes the feeds and brings the reactants to optimal temperature and pressure, and we only unfix downstream unit specifications:

# Set up Optimization Problem (Maximize Revenue)

# keep process pre-reaction fixed and unfix some post-process specs

m.fs.R101.conversion.unfix()

m.fs.R101.conversion_lb = Constraint(expr=m.fs.R101.conversion >= 0.75)

m.fs.R101.conversion_ub = Constraint(expr=m.fs.R101.conversion <= 0.85)

m.fs.R101.outlet_temp.deactivate()

m.fs.R101.outlet_t_lb = Constraint(

expr=m.fs.R101.control_volume.properties_out[0.0].temperature >= 405 * pyunits.K

)

m.fs.R101.outlet_t_ub = Constraint(

expr=m.fs.R101.control_volume.properties_out[0.0].temperature <= 505 * pyunits.K

)

# Optimize turbine work (or delta P)

m.fs.T101.deltaP.unfix() # optimize turbine work recovery/pressure drop

m.fs.T101.outlet_p_lb = Constraint(

expr=m.fs.T101.outlet.pressure[0] >= 10e5 * pyunits.Pa

)

m.fs.T101.outlet_p_ub = Constraint(

expr=m.fs.T101.outlet.pressure[0] <= 51e5 * 0.8 * pyunits.Pa

)

# Optimize Cooler outlet temperature - unfix cooler outlet temperature

m.fs.H102.outlet_temp.deactivate()

m.fs.H102.outlet_t_lb = Constraint(

expr=m.fs.H102.control_volume.properties_out[0.0].temperature

>= 407.15 * 0.8 * pyunits.K

)

m.fs.H102.outlet_t_ub = Constraint(

expr=m.fs.H102.control_volume.properties_out[0.0].temperature <= 480 * pyunits.K

)

m.fs.F101.deltaP.unfix() # allow pressure change in streams

m.fs.F101.isothermal = Constraint(

expr=m.fs.F101.control_volume.properties_out[0].temperature

== m.fs.F101.control_volume.properties_in[0].temperature

)

m.fs.S101.split_fraction[0, "purge"].unfix() # allow some gas recycle

m.fs.S101.split_fraction_lb = Constraint(

expr=m.fs.S101.split_fraction[0, "purge"] >= 0.10

) # min 10% purge

m.fs.S101.split_fraction_ub = Constraint(

expr=m.fs.S101.split_fraction[0, "purge"] <= 0.50

) # max 50% purge

print()

print("Solving optimization problem...")

opt_res = solver.solve(m, tee=True)

print("Optimal solution process results:")

report(m)

Solving optimization problem...

Ipopt 3.13.2: tol=1e-06

max_iter=100

******************************************************************************

This program contains Ipopt, a library for large-scale nonlinear optimization.

Ipopt is released as open source code under the Eclipse Public License (EPL).

For more information visit http://projects.coin-or.org/Ipopt

This version of Ipopt was compiled from source code available at

https://github.com/IDAES/Ipopt as part of the Institute for the Design of

Advanced Energy Systems Process Systems Engineering Framework (IDAES PSE

Framework) Copyright (c) 2018-2019. See https://github.com/IDAES/idaes-pse.

This version of Ipopt was compiled using HSL, a collection of Fortran codes

for large-scale scientific computation. All technical papers, sales and

publicity material resulting from use of the HSL codes within IPOPT must

contain the following acknowledgement:

HSL, a collection of Fortran codes for large-scale scientific

computation. See http://www.hsl.rl.ac.uk.

******************************************************************************

This is Ipopt version 3.13.2, running with linear solver ma27.

Number of nonzeros in equality constraint Jacobian...: 1236

Number of nonzeros in inequality constraint Jacobian.: 10

Number of nonzeros in Lagrangian Hessian.............: 494

Total number of variables............................: 410

variables with only lower bounds: 49

variables with lower and upper bounds: 334

variables with only upper bounds: 1

Total number of equality constraints.................: 405

Total number of inequality constraints...............: 10

inequality constraints with only lower bounds: 5

inequality constraints with lower and upper bounds: 0

inequality constraints with only upper bounds: 5

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

0 -2.8497829e+07 2.79e+04 1.00e+02 -1.0 0.00e+00 - 0.00e+00 0.00e+00 0

1 -2.8431118e+07 2.74e+04 9.77e+01 -1.0 8.82e+06 - 4.99e-02 1.94e-02h 1

2 -2.8430711e+07 2.74e+04 7.81e+02 -1.0 8.52e+06 - 3.76e-02 1.99e-04h 1

3 -2.8524881e+07 2.48e+04 1.61e+05 -1.0 6.46e+06 - 2.49e-04 9.25e-02f 1

4 -2.8526701e+07 2.48e+04 1.61e+05 -1.0 5.76e+06 - 5.84e-02 9.84e-04h 1

5 -2.8554187e+07 2.48e+04 1.60e+05 -1.0 1.49e+07 - 3.31e-03 8.96e-04h 1

6 -2.9123963e+07 2.43e+04 1.52e+05 -1.0 1.49e+07 - 1.23e-01 1.84e-02f 1

7 -2.9208669e+07 2.43e+04 1.51e+05 -1.0 9.71e+06 - 2.32e-02 2.78e-03h 1

8 -3.0003106e+07 2.36e+04 1.08e+06 -1.0 9.31e+06 - 1.92e-01 2.61e-02h 1

9 -3.1468193e+07 2.25e+04 1.09e+06 -1.0 8.71e+06 - 6.69e-02 4.91e-02f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

10 -3.1583879e+07 2.24e+04 1.14e+07 -1.0 5.51e+06 - 3.91e-01 3.89e-03h 1

11 -4.3112060e+07 3.08e+04 5.71e+06 -1.0 5.49e+06 - 1.57e-01 3.86e-01f 1

12 -4.3711568e+07 4.53e+04 5.09e+06 -1.0 3.67e+06 - 8.46e-02 2.88e-02h 1

13 -4.3718128e+07 4.53e+04 1.94e+06 -1.0 3.57e+06 - 5.80e-01 3.23e-04h 1

14 -4.3760522e+07 4.51e+04 4.15e+07 -1.0 3.56e+06 - 4.25e-01 5.93e-03h 1

15 -4.4646098e+07 7.99e+04 5.37e+07 -1.0 3.54e+06 - 6.75e-01 1.23e-01h 4

16 -6.6609972e+07 4.70e+04 6.17e+06 -1.0 3.14e+06 - 7.83e-01 9.90e-01H 1

17 -6.5995606e+07 4.70e+04 3.11e+06 -1.0 2.01e+07 - 3.61e-03 3.25e-03h 5

18 -6.5244378e+07 4.71e+04 3.13e+07 -1.0 1.74e+07 - 4.59e-05 4.34e-03h 5

19 -6.4062633e+07 2.26e+03 9.67e+06 -1.0 7.97e+04 - 3.33e-04 9.87e-01h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

20 -6.4049029e+07 1.77e+03 8.54e+03 -1.0 2.65e+03 - 9.89e-01 1.00e+00h 1

21 -6.5078519e+07 1.26e+03 4.14e+05 -1.0 1.04e+05 - 9.50e-01 9.92e-01f 1

22 -7.5331212e+07 1.38e+05 3.86e+06 -1.0 1.20e+06 - 2.40e-01 1.00e+00f 1

23 -7.4656465e+07 9.99e+04 2.12e+06 -1.0 1.07e+05 -4.0 9.90e-01 2.77e-01h 1

24 -7.4647261e+07 9.94e+04 2.08e+06 -1.0 7.74e+04 -4.5 5.39e-01 5.21e-03h 1

25 -7.4611366e+07 9.73e+04 2.02e+06 -1.0 7.24e+04 -5.0 1.00e+00 2.07e-02h 1

26 -7.4417200e+07 8.61e+04 1.78e+06 -1.0 7.10e+04 -5.4 5.90e-01 1.15e-01h 1

27 -7.4386538e+07 8.46e+04 1.75e+06 -1.0 7.83e+04 -5.9 1.23e-02 1.80e-02h 1

28 -7.2736888e+07 3.01e+02 1.72e+06 -1.0 1.09e+05 -6.4 1.06e-04 1.00e+00h 1

29 -7.2723098e+07 1.43e-01 6.52e+02 -1.0 5.95e+02 -6.9 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

30 -7.2723237e+07 7.89e-05 2.09e+01 -1.7 1.63e+02 -7.3 1.00e+00 1.00e+00f 1

31 -8.6816248e+07 8.68e+03 9.78e+05 -2.5 5.17e+06 - 2.86e-02 5.98e-01f 1

32 -8.6800100e+07 8.39e+03 5.89e+05 -2.5 1.65e+04 -7.8 9.53e-01 3.34e-02h 1

33 -8.6300514e+07 1.51e+01 7.15e+04 -2.5 2.25e+04 -8.3 8.28e-02 1.00e+00h 1

34 -8.6315409e+07 4.51e-03 1.67e+00 -2.5 3.37e+03 -8.8 1.00e+00 1.00e+00h 1

35 -8.6355967e+07 4.54e-02 7.17e-02 -2.5 1.03e+04 -9.2 1.00e+00 1.00e+00f 1

36 -8.6484921e+07 3.89e-01 3.04e+03 -5.7 3.04e+04 -9.7 9.89e-01 1.00e+00f 1

37 -8.6863742e+07 3.35e+00 6.38e-01 -5.7 9.16e+04 -10.2 1.00e+00 9.94e-01f 1

38 -8.7407159e+07 7.89e+00 3.54e-01 -5.7 2.74e+05 -10.7 1.00e+00 4.78e-01f 1

39 -9.0728210e+07 2.04e+02 2.21e+00 -5.7 8.01e+05 -11.2 1.00e+00 1.00e+00f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

40 -9.9495406e+07 6.13e+02 3.85e+00 -5.7 2.39e+06 -11.6 1.00e+00 9.06e-01f 1

41 -9.9495429e+07 6.13e+02 3.85e+00 -5.7 5.53e+06 -12.1 1.07e-01 1.10e-06h 1

42 -1.0301585e+08 3.81e+04 2.43e+01 -5.7 7.11e+06 -12.6 3.99e-01 1.44e-01f 1

43 -1.0301585e+08 3.81e+04 3.36e+01 -5.7 1.39e+06 - 6.86e-01 1.25e-06h 2

44 -1.0436645e+08 3.42e+05 1.56e+01 -5.7 2.02e+06 - 1.00e+00 1.00e+00h 1

45 -1.0441854e+08 3.22e+05 1.44e+01 -5.7 4.91e+06 - 9.43e-01 7.95e-02h 1

46 -1.0439096e+08 2.72e+05 1.22e+01 -5.7 1.25e+07 - 2.29e-01 1.54e-01h 1

47 -1.0436186e+08 2.07e+05 9.28e+00 -5.7 6.35e+05 - 1.00e+00 2.38e-01h 1

48 -1.0427962e+08 1.89e+04 8.38e-01 -5.7 2.21e+05 - 1.00e+00 9.09e-01h 1

49 -1.0427372e+08 1.22e+01 8.52e-02 -5.7 2.02e+04 - 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

50 -1.0427510e+08 3.31e+02 1.55e+00 -5.7 5.86e+04 -13.1 1.00e+00 9.55e-01h 1

51 -1.0427510e+08 2.94e+02 5.87e+01 -5.7 2.24e+04 - 7.65e-02 1.13e-01f 1

52 -1.0427509e+08 1.51e-03 1.08e-01 -5.7 8.91e+03 - 1.00e+00 1.00e+00f 1

53 -1.0427919e+08 3.06e+03 5.51e+01 -5.7 1.66e+05 -13.5 1.00e+00 1.00e+00f 1

54 -1.0427839e+08 2.40e+03 4.05e+01 -5.7 1.34e+05 - 4.18e-01 2.55e-01h 1

55 -1.0427605e+08 1.01e+03 2.12e+01 -5.7 9.49e+04 - 4.92e-01 1.00e+00h 1

56 -1.0427605e+08 6.84e-03 5.30e+01 -5.7 1.43e+03 - 2.80e-01 1.00e+00h 1

57 -1.0427605e+08 6.93e-04 5.08e-03 -5.7 1.97e+02 - 1.00e+00 1.00e+00h 1

58 -1.0427606e+08 1.10e-02 4.86e+00 -5.7 3.32e+02 -10.4 4.14e-01 1.00e+00h 1

59 -1.0427605e+08 2.11e-03 5.96e-01 -5.7 2.09e+02 - 2.89e-01 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

60 -1.0427605e+08 7.76e-05 1.67e-01 -5.7 3.44e+02 - 5.92e-01 1.00e+00h 1

61 -1.0427606e+08 1.07e-03 3.54e-02 -5.7 1.20e+03 - 4.52e-01 1.00e+00h 1

62 -1.0427606e+08 1.84e-02 6.27e-02 -5.7 5.23e+03 - 3.18e-01 1.00e+00h 1

63 -1.0427613e+08 2.01e+00 9.36e-03 -5.7 5.45e+04 - 1.26e-01 1.00e+00h 1

64 -1.0427676e+08 1.61e+02 1.39e-02 -5.7 6.86e+06 - 8.97e-03 7.04e-02h 3

65 -1.0427678e+08 1.30e-01 1.17e-04 -5.7 7.26e+02 -10.9 1.00e+00 1.00e+00h 1

66 -1.0427727e+08 9.59e+01 5.94e-03 -5.7 5.11e+06 - 1.07e-01 6.92e-02h 3

67 -1.0427802e+08 3.15e+02 6.28e-02 -5.7 5.67e+06 - 4.89e-01 9.21e-02h 2

68 -1.0427841e+08 3.63e+02 7.79e-02 -5.7 6.06e+06 - 2.53e-01 4.21e-02h 2

69 -1.0427881e+08 4.10e+02 1.51e-01 -5.7 5.10e+06 - 1.00e+00 4.94e-02h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

70 -1.0427883e+08 1.43e-01 9.49e-05 -5.7 1.47e+04 - 1.00e+00 1.00e+00h 1

71 -1.0427883e+08 7.08e-03 1.45e-08 -5.7 2.57e+03 - 1.00e+00 1.00e+00h 1

72 -1.0427884e+08 5.67e-04 5.09e-06 -8.6 1.47e+03 - 1.00e+00 1.00e+00h 1

73 -1.0427884e+08 1.86e-09 4.07e-13 -8.6 6.91e-01 - 1.00e+00 1.00e+00h 1

74 -1.0427884e+08 6.98e-10 9.29e-12 -10.9 1.99e+00 - 1.00e+00 1.00e+00h 1

Number of Iterations....: 74

(scaled) (unscaled)

Objective...............: -1.6119507851269790e+02 -1.0427883997850096e+08

Dual infeasibility......: 9.2924871475505862e-12 6.0114104549747288e-06

Constraint violation....: 1.0186340659856796e-10 6.9849193096160889e-10

Complementarity.........: 1.4067955349081705e-11 9.1007124920133822e-06

Overall NLP error.......: 1.0186340659856796e-10 9.1007124920133822e-06

Number of objective function evaluations = 109

Number of objective gradient evaluations = 75

Number of equality constraint evaluations = 109

Number of inequality constraint evaluations = 109

Number of equality constraint Jacobian evaluations = 75

Number of inequality constraint Jacobian evaluations = 75

Number of Lagrangian Hessian evaluations = 74

Total CPU secs in IPOPT (w/o function evaluations) = 0.296

Total CPU secs in NLP function evaluations = 0.086

EXIT: Optimal Solution Found.

Optimal solution process results:

Extent of reaction: 311.30698549500477

Stoichiometry of each component normalized by the extent:

CH4 : -0.0

H2 : -2.0

CH3OH : 1.0

CO : -1.0

These coefficients should follow 1*CO + 2*H2 => 1*CH3OH

Reaction conversion: 0.8500000099996615

Reactor duty (MW): -59.34022107299142

Duty from Reaction (MW)): 28.216865165267233

Compressor work (MW): -1.0259209299738811e-24

Turbine work (MW): -2.4913012083835544

Feed Mixer outlet temperature (C)): 20.051714213753428

Recycle Mixer outlet temperature (C)): 41.543214378017694

Feed Compressor outlet temperature (C)): 41.543214378017694

Feed Compressor outlet pressure (Pa)): 5100000.0

Heater outlet temperature (C)): 215.0

Reactor outlet temperature (C)): 231.85000478420352

Turbine outlet temperature (C)): 141.5003786288168

Turbine outlet pressure (Pa)): 1487177.2483577363

Cooler outlet temperature (C)): 52.56999699056837

Flash outlet temperature (C)): 134.0

Purge percentage (amount of vapor vented to exhaust): 9.999999000026644 %

Methanol recovery(%): 92.05882105498137

annualized capital cost ($/year) = 259559.90821304682

operating cost ($/year) = 525130020.70955175

sales ($/year) = 140033684437.2827

raw materials cost ($/year) = 35229454878.16397

revenue (1000$/year)= 104278839.97850098

====================================================================================

Unit : fs.H2 Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Outlet

Total Molar Flowrate mole / second 637.20

Total Mole Fraction CH4 dimensionless 1.0000e-06

Total Mole Fraction CO dimensionless 1.0000e-06

Total Mole Fraction H2 dimensionless 1.0000

Total Mole Fraction CH3OH dimensionless 1.0000e-06

Molar Enthalpy joule / mole -142.40

Pressure pascal 3.0000e+06

====================================================================================

====================================================================================

Unit : fs.CO Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Outlet

Total Molar Flowrate mole / second 316.80

Total Mole Fraction CH4 dimensionless 1.0000e-06

Total Mole Fraction CO dimensionless 1.0000

Total Mole Fraction H2 dimensionless 1.0000e-06

Total Mole Fraction CH3OH dimensionless 1.0000e-06

Molar Enthalpy joule / mole -1.1068e+05

Pressure pascal 3.0000e+06

====================================================================================

====================================================================================

Unit : fs.EXHAUST Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Inlet

Total Molar Flowrate mole / second 22.743

Total Mole Fraction CH4 dimensionless 4.1946e-05

Total Mole Fraction CO dimensionless 0.24155

Total Mole Fraction H2 dimensionless 0.64134

Total Mole Fraction CH3OH dimensionless 0.11706

Molar Enthalpy joule / mole -47286.

Pressure pascal 7.4845e+06

====================================================================================

====================================================================================

Unit : fs.CH3OH Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units Inlet

Total Molar Flowrate mole / second 308.65

Total Mole Fraction CH4 dimensionless 1.0000e-08

Total Mole Fraction CO dimensionless 1.0000e-08

Total Mole Fraction H2 dimensionless 1.0000e-08

Total Mole Fraction CH3OH dimensionless 1.0000

Molar Enthalpy joule / mole -2.3792e+05

Pressure pascal 7.4845e+06

====================================================================================